HIF Type Carburetter: Dismantling

1

(a) Thoroughly clean the outside of the carburetters.

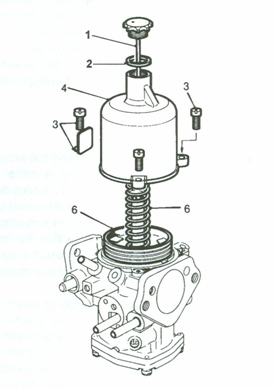

(b) Standard suction chambers. Remove the piston damper (1) and its washer (2), if fitted.

(c) Unscrew the suction chamber retaining screws (3) and remove the identity tag.

(d) Lift the chamber assembly (4) vertically from the body without tilting it

2

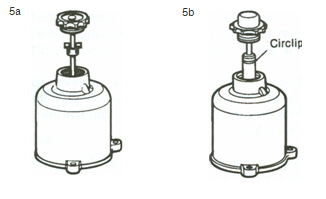

Ball bearing suction chambers (early type). Hold the piston firmly and pull the suction chamber, taking care not to bend the damper rod, until the bearing retainer is freed from the piston rod (5a). Remove the damper. Ball bearing suction chambers (later type). Remove the piston damper. Lift the piston and remove the bearing retaining circiip (5b).

3

(a) Separate the suction chamber, the spring and the piston assembly (6) and empty the oil from the piston rod.

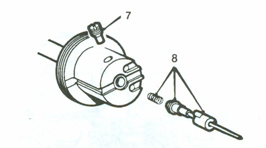

(b) Unscrew the needle guide locking screw (7).

(c) Withdraw the needle, guide and spring (8).

4

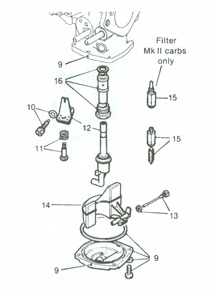

(a) Mark the bottom cover-plate and body to ensure correct reassembly (9), unscrew the retaining screws and remove the cover complete with sealing ring.

(b) Remove the jet adjusting screw complete with 'O' ring (10).

(c) Remove the jet adjusting lever retaining screw and spring (11).

(d) Withdraw the jet complete with adjusting lever and disengage the lever (12).

(e) Remove the float pivot spindle and fibre washer (13).

(f) Withdraw the float (14).

(g) Remove the needle valve (15) and unscrew the valve seat. (Complete with filter, types HIF38 & HIF44 only).

(h) Unscrew the jet bearing locking nut and withdraw the bearing complete with its washer (16).

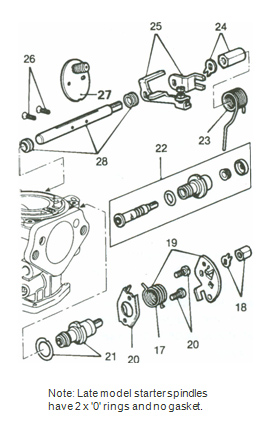

5

(a) Note the location of the ends of the fast idle cam lever return spring (17).

(b) Unlock and remove the cam lever retaining nut and locking washer (18).

(c) With the return spring held towards the carburetter body, prise off the cam lever and remove the return spring (19).

(d) Unscrew the starter unit retaining screws and remove the cover-plate (20).

(e) Withdraw the starter unit assembly and remove its gasket (21). Note: On later starter units the cover plate and starter body are designed not to be separated. This ensures greater accuracy of starter operation.

(f) Withdraw the valve spindle and remove the 'O' ring, seal and dust cap (22).

6

(a) Note the location and loading of the ends of the throttle lever return spring and remove the spring (23).

(b) Unlock and remove the nut and tab washer retaining the throttle levers (24).

(c) Remove the throttle lever and throttle actuating lever (25). These may vary quite considerably from those shown.

(d) Remove the throttle disc retaining screws (26).

(e) Close the throttle and mark the position of throttle disc in relation to the carburetter flange. Do not mark the disc in the vicinity of the overrun valve. Open the throttle and carefully withdraw the disc from the throttle spindle taking care not to damage the overrun valve (27).

(f) Withdraw the throttle spindle and remove its seals (28), noting the way it is fitted in relation to carburetter body to ensure the correct reassembly.