Mechanical Fuel Pump: Fault Diagnosis

Suspected Fuel Starvation

To check the fuel flow, disconnect the carburetter end of the fuel line and place the line into a suitable container. With the ignition switched off rotate the engine.

(a) If the flow is normal, examine the carburetter for obstructed float chamber needle seating or gummed needle valve.

(b) If the flow is normal initially, but falls off rapidly, check for adequate fuel tank venting by removing the filler cap. (c) Other causes of a low fuel flow are a choked pump or tank filter.

(d) If quantities of air bubbles emerge from the fuel line whilst it is immersed in a container, check for an air leak in the inlet fuel line.

(e) AUF 700 Type: If there is no flow, check as in (d) and if no air bubbles are present, dismantle the pump and examine the valves and the diaphragm.

Do not pass compressed air through the pump.

Dry Testing

The following sequence of tests are recommended when the fuel pump performance is suspect or after dismantling and reassembly.

Suction Test

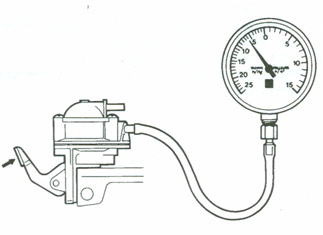

(a) Mount the pump in a soft-jawed vice and connect the inlet union with the tube supplied to special gauge 18G 1116. (AUF 700 type pump shown in diagrams.)

(b) Operate the pump lever through three full strokes. AUF 700 Type: A minimum vacuum reading of 152.4 mm (6.0") Hg should be obtained which must not drop at a greater rate than 50.8 mm (2.0") in 15 seconds. AUF 800 Type: A minimum vacuum reading of 228.6 mm (9.0") Hg should be obtained which must not drop at a greater rate than 76.2 mm (3.0") in 5 seconds.

(c) Disconnect the gauge before continuing.

Delivery Test

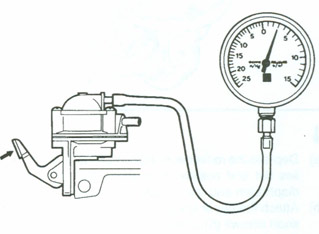

(a) With the pump still mounted in the vice, connect the outlet union to the gauge 18G 1116 using the same tube.

(b) Operate the pump lever through two full strokes. UF 700 Type: A minimum reading of 0.21 kg/cm2 (3.0 Ib/in2) should be obtained which should not fall by more than 0.0035 kg/cm2 (0.5Ib/in2) in 15 seconds. AUF 800 Type: A minimum reading of 0.42 kg/cm2 (6 lb/in") should be obtained which should not fall by more than 0.140 kg/cm2 (2 Ib/in2) in 5 seconds.