HIF Type Carburetter: Inspection

1

(a) Examine the throttle spindle and its bearings in the carburetter body; check for any excessive play, and renew any parts as necessary.

(b) Examine the float needle, seating and filter where fitted for damage, contamination and excessive wear; renew if necessary.

(c) Examine all rubber seals and 'O' rings for any damage or deterioration; renew as necessary. The cover plate sealing ring and starter 'O' ring must be renewed.

(d) Check condition of all fibre washers and gaskets; renew as necessary.

2

(a) Examine the carburetter body for cracks and damage, and for security of the brass connections and the piston key.

(b) Clean the inside of the suction chamber and the piston rod guide with fuel or mentholated spirit (denatured alcohol) and wipe dry. Abrasives must not be used.

(c) Examine the suction chamber and piston for damage and signs of scoring.

3

Ball bearing suction chambers. Check that all the balls are in the piston ball race (2 rows, 6 per row). Fit the piston into the suction chamber, without the damper and spring, hold the assembly in a horizontal position and spin the piston. The piston should spin freely in the suction chamber without any tendency to stick.

4

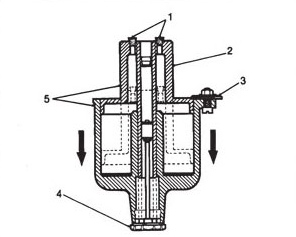

The following timing check applies only to standard suction chambers and need only be carried out if the cause of the carburetter malfunction which necessitated the dismantling has not been located.

(a) Temporarily plug the piston transfer holes (1).

(b) Fit the piston into the chamber without its spring (2).

(c) Fit a nut and screw, with a large flat washer under the nut, into one of the suction chamber fixing holes, positioning the washer so that it overlaps chamber bore (3).

(d) Fit the damper and washer (4).

(e) Check that the piston is fully home in the chamber, invert the assembly to allow the chamber to fall away until the piston contacts the washer (5).

(f) Check the time taken for the chamber to fall the full extent of the piston travel. For carburetters 38.0 mm (1.5 in) to 47.6 mm (1 7/8 in) bore, the time taken should be 5 to 7 seconds.

(g) If the times are exceeded check the piston and chamber for presence of oil, foreign matter and damage. If after re-checking the time is still not within these limits, renew the suction chamber assembly.