H Type Carburetter: Routine Servicing

Jet centering

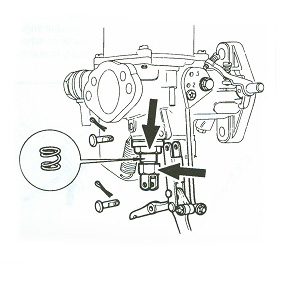

The piston should fall freely onto the carburetter bridge with a click when the lifting pin is released with the jet in the fully up position. If it will only do this with the jet lowered then the jet unit requires re-centering. This is done as follows:

- Remove the jet control linkage and swing it to one side.

- Mark for reassembly and withdraw the jet, remove the jet locking spring, replace the adjusting nut and screw it up as far as it will go.

- Replace the jet, keeping the jet head in the correct relative position to the control lever.

- Slacken the jet locking nut until the assembly is free to rotate.

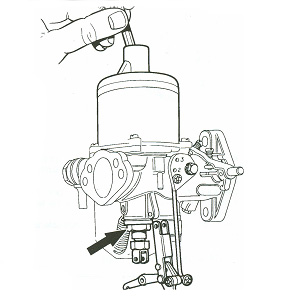

- Remove the piston damper and apply pressure to the top of the piston rod with a pencil.

- Tighten the jet locking nut keeping the jet head in the correct position and the jet hard up against the adjusting nut.

- Finally check the action of the piston again.

- Reassemble the controls.

- Refill the piston dampers with thin oil as in tuning section (8).

Cleaning

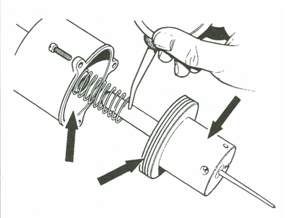

At the recommended intervals mark for reassembly and carefully remove the piston/suction chamber unit.

Using a petrol or meths moistened cloth, clean the inside bore of the suction chamber and the two diameters of the piston.

Lightly oil the piston rod only and reassemble as marked.

Float Chamber Fuel Level

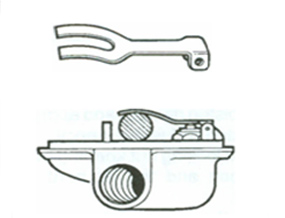

Remove the float chamber lid and invert it.

With the needle on its seating insert a 11.0 mm (7/16 in) diameter round bar between the forked lever and the lip of the float chamber lid.

The prongs of the lever should just rest on the bar. If not, carefully bend the lever until they do.

Needle size and position

The needle size is determined during engine development and will provide the correct mixture strength except when under extremes of temperature, humidity, or altitude; e.g. a weaker needle will be necessary at altitudes exceeding 1800 m (6,000 ft.) If modifications are made to the engine: (e.g. camshaft, compression ratio, air cleaner or exhaust system) a different needle may be necessary to maintain performance.

- Slacken the needle clamping screw, extract the needle, and check its identifying mark against the recommendation.

- Fit the correct needle and lock it in position so that the shoulder on the shank is flush with the piston base.

- Reassemble the piston/suction chamber unit.