Dual Type Electric Fuel Pumps

With the exception of the inlet valve arrangement and the external wiring, the two types of dual electric pump are of similar general construction.

Each pump comprises three main assemblies: the body assembly (1 off), diaphragm, armature and magnet assembly (2 off) and the contact breaker assembly (2 off). All numbers refer to the diagram on page 63.

The Body

AUF 400/AZX 1400 Type

The inlet union (49) has uninterrupted communication with an inlet air bottle as a flow-smoothing aid. Both pumping chambers are fed from this inlet and pump fuel to a common delivery chamber.

AUF 500/AZX 1500 Type

The body (1) is a die-casting into which the main inlet union (49) is screwed; this is connected to one side of a divided compartment which is in communication with an inlet air bottle separated from the corresponding inlet air bottle which serves the second inlet connection. The delivery chamber is common to both primary and secondary delivery.

Both Types

The delivery chamber is bounded by a flexible plastic diaphragm (54), separating it from a sealed volume of air contained in the air bottle cover (51) and sealed by the O ring (53). The inlet valve assembly (35) comprises a plastic disc permanently assembled in a pressed-steel cage with a dome-shaped filter (32) provided on its entry side. The outlet valve (36) is an identical assembly, but reversed in direction. Both valves are held in position by valve covers (61) and retained by a clamp plate (62) with two self-tapping screws (63). The inlet valve (35) allows passage to the pumping chamber formed by a shallow depression in the body casting and bounded by the diaphragm (2).

The Diaphragm, Armature and Magnet Assembly

The diaphragm (2) is clamped at its outer edge between the coil housing (5) and the body, and attached at its centre to the iron armature. The armature spindle passes freely through the magnet core, and is screwed into a trunnion carried by the inner rocker (15). A plastic armature guide plate (7) centralises the armature and allows freedom of movement in a longitudinal direction. An atmospheric vent may be fitted to the coil housing.

The Contact Breaker Assembly

This assembly consists of a bakelite pedestal moulding (16) which carries two rockers, outer and inner (15), both hinged to the moulding at one end by the rocker spindle and interconnected at their top ends by two small toggle springs arranged to give a 'throw over' action. This inner rocker, as mentioned, carries a trunnion into which the armature spindle is screwed. The outer rocker is fitted with one or two tungsten points which contact other tungsten points carried by the spring blade (22). One end of the coil (5) is connected electrically to the spring blade and the other end is connected to the terminal stud (17). A short length of flexible wire connects the outer rocker to one of the screws securing the pedestal moulding to the coil housing, thus providing an earth return. This tag must then be thoroughly earthed to the body or chassis of the vehicle via the earthing screw (9). A non-return valve (64) may be fitted to the end-cover moulding (33) to aid the circulation of air through the contact-breaker chamber. A diode-resistor (34), where fitted, is in parallel with the points as a spark suppressor to increase their life. Some earlier models were fitted with a condenser rather than a diode-resistor.

Operation

When the pump is at rest the outer rocker lies so that the tungsten points make contact. When switched on, current passes from the terminal stud (17) through the coil, back to the spring blade (22) through the points and so to earth, thus energizing the coil and attracting the armature (2). The armature, together with the diaphragm assembly, moves towards the coil, against pressure from the armature spring (4), drawing fuel through the inlet valve into the pumping chamber. When the armature has travelled well towards the end of its stroke the 'throw over' mechanism operates and the outer rocker moves rapidly backwards, thus separating the contact points and breaking the circuit.

The armature and diaphragm will now move away from the coil under the influence of the armature spring, thereby expelling the fuel through the outlet valve at a rate determined by the requirements of the engine. As the armature approaches the end of its stroke, away from the coil, the 'throw over' mechanism again operates, the tungsten points re-make contact, and the cycle of operations is repeated.

Installation

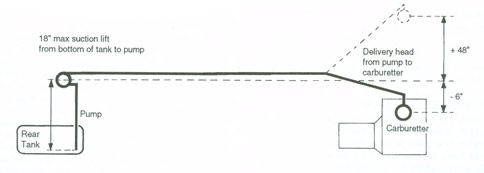

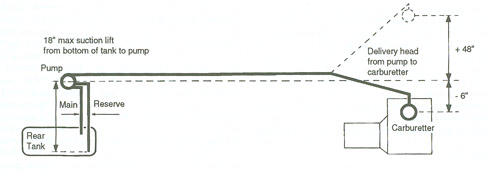

Dual electrical pumps, because of their high delivery pressure, are very suitable for mounting over the rear fuel tank, in which position they are also free from vaporizing troubles due to high under-bonnet temperatures.

The coil housing vent connector and end cover vent (where fitted) should be piped to a region of dry air, for example the car interior or luggage compartment. The following diagrams give typical installation configurations.

AUF 400/AZX 1400 Pump Installation

AUF 500/AZX 1500 Pump Installation

Performance

| Type | Voltage | Minimum Voltage* | Current at Minimum Voltage |

| AUF 400/AZX 1400 AUF 500/AZX 1500 |

13.5 13.5 |

9.5 9.5 |

1.5A 1.5A |

| Type | Capacity | Bore of Pipe | Maximum Line Pressure |

| AUF 400/AZX 1400 AUF 500/AZX 1500 |

30 gal/hr 12.5 gal/hr |

0.312" 0.312" |

2.7/3.8 Ib/in2 2.7/3.8 Ib/in2 |