HS4C and HS8 Carburetter: Dismantling

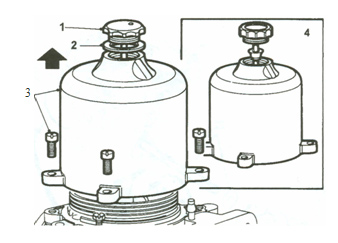

1

(a) Thoroughly clean the outside of the carburetter.

(b) Standard suction chambers. Remove the piston damper (1) and its washer (2), if fitted.

(c) Unscrew the suction chamber retaining screws (3).

(d) Lift the chamber assembly vertically from the body without tilting it (4).

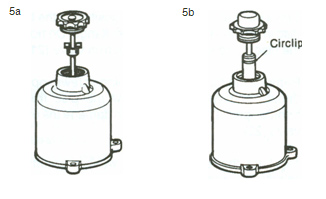

2

Ball bearing suction chambers (early type). Hold the piston firmly and pull the suction chamber, taking care not to bend the damper rod, until the bearing retainer is freed from the piston rod (5a). Remove the damper. Ball bearing suction chambers (later type). Remove the piston damper. Lift the piston and remove the bearing retaining circlip (5b). Note: ball bearing suction chambers are not available for HS8 carburetters.

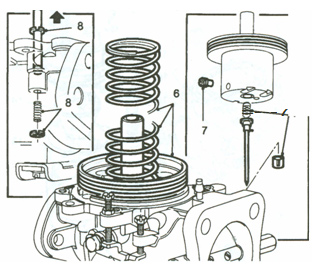

3

(a) Separate the suction chamber, the spring and the piston assembly and empty the oil from the piston rod (6).

(b) Unscrew the needle guide locking screw, then withdraw the needle, guide and spring (7).

(c) Remove the piston lifting pin circlip and spring, withdraw the pin from the body (8).

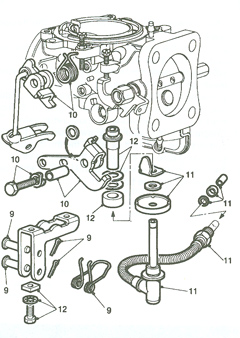

4

(a) Remove the split pins retaining the jet spring anchor pin and jet fork pivot pin. Remove the pins, spring and jet fork from the bracket (9).

(b) Release the cam lever return spring from its lug, remove the bolt, washers, cam lever, bush and link arm assembly (10).

(c) Unscrew the jet tube sleeve nutfrom the float chamber and withdraw the jet assembly complete with centring washer, copper washer and ferrule at the end of the jet tube (11).

(d) Remove the bolts, starlock washers and spacers securing the fork bracket to the carburetter body and withdraw the jet bearing together with the bush and Bellville washers (12).

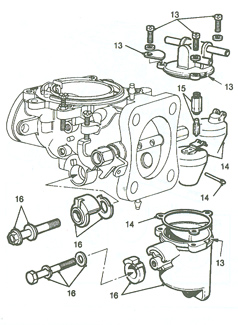

5

(a) Mark the relative position of the float lid and chamber, remove the float lid retaining screws, washers and identification tag (13).

(b) Remove the float lid and gasket, withdraw the float hinge pin and remove the float (14).

(c) Withdraw the float needle and unscrew the needle seat (15).

(d) Remove the float chamber securing bolt, float chamber and metal spacer or rubber mounting and backing washer (16).

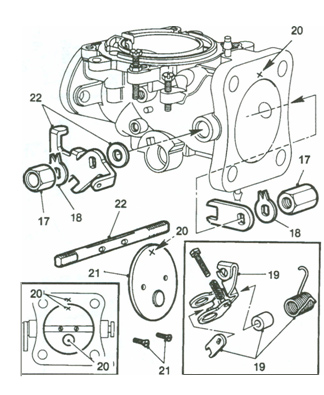

6

(a) HS4C - release the return spring from the throttle lever.

(b) Bend back the tabs and remove the throttle spindle nut(s) (17) and tab washer(s) (18).

(c) HS4C - withdraw the lost motion lever, throttle actuating lever, return spring and spacer (19).

(d) Close the throttle and mark the position of the throttle disc in relation to the carburetter flange (20). Do not mark the disc in the vicinity of the overrun valve.

(e) Unscrew the disc retaining screws, open the throttle and ease the disc from its slot in the throttle spindle (21) taking care not to damage the overrun valve.

(f) Remove the throttle lever and washer and withdraw the spindle from the body (22).